![Back to homepage [PREFA KOMPOZITY,a.s. logo]](https://www.prefa-kompozity.cz/en/wp-content/themes/prefakompozityen/images/prefa-kompozity-logo-new.png)

Basic products

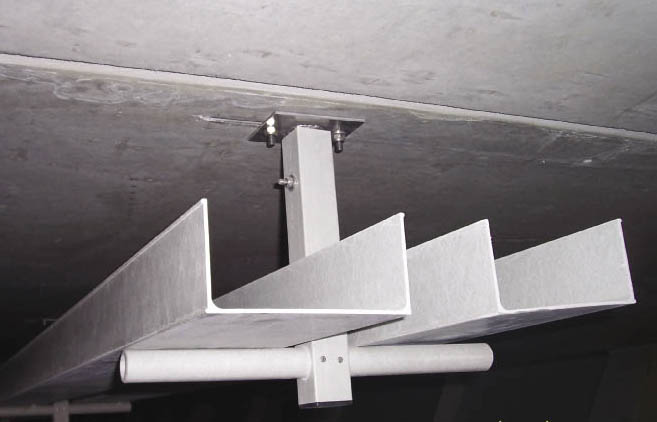

Structures

COMPOSITE RAILINGS

COMPOSITE RAILINGS WALL-MOUNTED AND FREE-STANDING COMPOSITE LADDERS

WALL-MOUNTED AND FREE-STANDING COMPOSITE LADDERS CABLE RUNS

CABLE RUNS COMPOSITE FOOTBRIDGES

COMPOSITE FOOTBRIDGES COMPOSITE STAIRCASES

COMPOSITE STAIRCASES WATERWORKS STRUCTURES

WATERWORKS STRUCTURES ENERGY INDUSTRY PRODUCTS

ENERGY INDUSTRY PRODUCTS

OTHERS

LAMINATED PRODUCTS

LAMINATED PRODUCTS PREFAPREG SMC

PREFAPREG SMC BMC MATERIALS

BMC MATERIALS PRESSING

PRESSING GLUES

GLUES PREFA REBAR COMPOSITE REINFORCEMENT

PREFA REBAR COMPOSITE REINFORCEMENT custom products

custom products

COMPANY NAME AND ADDRESS

PREFA KOMPOZITY, a.s., Kulkova 10/4231, 615 00 Brno, Czech Republic

The Company’s business registration number (IČ) is 26949881,

its VAT registration number (DIČ) is CZ26949881.

It is entered into the Commercial Registry of the Regional Court of Brno, File B-4276.

Tel.: +420 541 583 297, +420 541 583 208

email: kompozity@prefa.cz

MANUFACTURING PLANT AND WAREHOUSE

Havránkova 11, 619 00 Brno – Dolní Heršpice, Czech Republic

COMPANY MANAGEMENT

Chairman of the Board

Ing. Miloš Filip • tel.: +420 541 583 292 • filip@prefa.cz

Director of the company

Ing. Pavel Stryk • tel.: +420 541 583 208, +420 728 082 107 • stryk@prefa.cz

TECHNOLOGY AND SALES

Sales manager

Ing. Marek Šlapanský • tel.: +420 541 583 297, +420 606 610 178 • slapansky@prefa.cz

Sales assistant

Petra Stryková • tel.: +420 606 076 043 • strykova@prefa.cz

Project and technology manager

Ing. Michal Došlík • tel.: +420 541 583 241, +420 734 755 956 • doslik@prefa.cz

DEVELOPMENT AND INNOVATION DIVISION

Director of Development and innovation division

Ing. Jan Prokeš, Ph.D. • tel.: +420 724 054 563 • prokes@prefa.cz

Development technician

Ing. Ondřej Sedláček • tel.: +420 724 954 756 • sedlacek@prefa.cz

Development technician

Ing. Ondřej Bezděk • tel.: +420 720 669 848 • bezdek@prefa.cz

PRODUCTION

Director of manufacturing plant and warehouse

Ing. Jiří Bechný • tel.: +420 543 521 419, +420 602 510 758 • bechny@prefa.cz

Contact us:

Product certificates

| Profiles PREFEN | |

| Gratings PREFAGRID and PREFAPOR | |

| Covers PREFAPLATE | |

| Railings PREFASAF | |

| Ladder PREFALAD | |

| Composite reinforcement PREFACARB (cz) | |

| Reinforcing rods PREFA REBAR (cz) |

Declaration of conformity / Declaration of performance

| Profiles PREFEN (DoC) | |

| Gratings PREFAGRID a PREFAPOR (DoC) | |

| Covers PREFAPLATE (DoC) | |

| Railings PREFASAF (DoC) | |

| Ladders PREFALAD (DoC) | |

| Shaft ladders PREFALAD (DoP) | |

| Composite reinforcement PREFACARB (DoP – cz) | |

| Reinforcing rods PREFA REBAR (DoC – cz) |

Assessment

| Fire interaction class C-s2, d0, construction products (cz) | |

| Fire interaction class B fl-s1, flooring materials (cz) | |

| Antistatic (cz) | |

| PREFEN – surface resistance | |

| Statement of the Mining Office (cz) | |

| Reference list – Utility tunnel (cz) | JPG |

| Thermal conductivity (cz) | |

| Anti-slip properties (cz) | |

| Contact with drinking water | |

| Insulating properties of ladders (cz) |

ISO Certificate

| Certificate ISO 9001:2016 | |

| Certificate ISO 14001:2016 |

Catalogs

| Product catalog 2019 | |

| Railings and covers (cz) | |

| Leaflet covers | |

| FRP concrete reinforcement (cz) | |

| Leaflet PREFACARB (cz) | |

| Leaflet PREFEN 600HT (cz) | |

| Leaflet SMC PREFAPREG (cz) | |

| Profiles dimensioning (cz) | |

| Key features of PREFEN profiles (cz) |

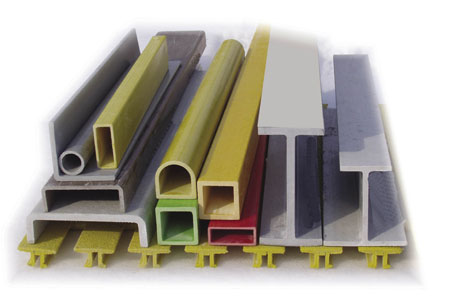

Program PREFEN

| Calculation tables for PREFEN profiles (in Czech l.) | XLS format |

Production technology

WHAT ARE COMPOSITE MATERIALS?

Generally speaking, a composite is any material consisting of at least two principal components with significantly different physical properties. PREFA KOMPOZITY manufactures composite materials consisting of a binder matrix and fiber reinforcement. Most of our materials use organic polymer resins as the matrix and glass fiber as reinforcement; that is, they are fiber-reinforced plastics. Our fiber-reinforced plastics are sold under the trade name PREFEN.

Aside from production technology, the key parameters determining the properties of composite materials are:

Matrix type

- Polyester the most common resin type, frequently used in construction

- Vinylester – more demanding applications, including chemically corrosive environments and high mechanical and thermal load

- Epoxide – applications most demanding on mechanical and electrical properties and chemical stability

Reinforcing fiber type

- Glass – standard mechanical properties

- Carbon – high elastic modulus and high dynamic load applications

- Other fibers (principally aramid and basalt) for specific applications

Admixtures

The matrix resin may include a variety of admixtures to improve the properties of the resulting material; these include e.g. fire-retardants, UV stabilizers, electrical conductivity enhancers, etc.

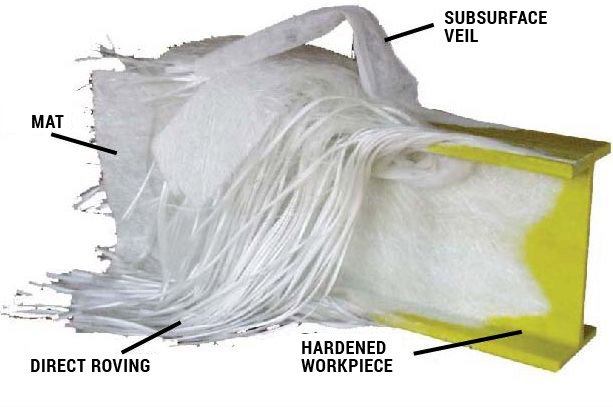

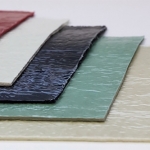

Subsurface veil

An often underappreciated feature of composite materials, the veil enhances the product’s appearance and has a variety of practical functions; it is particularly essential in chemically corrosive environments and UV-intensive applications.

TECHNOLOGIES USED BY PREFA KOMPOZITY:

- Pultrusion – opened and closed profiles, rods, plates, spiral-wound rods

- Winding – round tubes

- Molding – PREFAGRID walk-over and load-bearing gratings

- Manual lamination – cover surfaces and edges, custom products

- SMC – semiproduct for pressed products, manhole covers

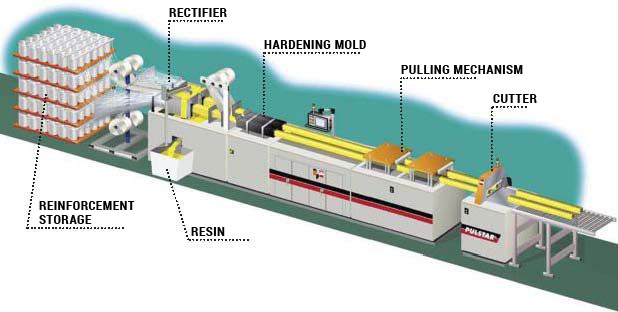

PULTRUSION TECHNOLOGY

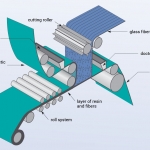

Pultrusion is a process for the continuous production of reinforced resins of varied shapes and lengths by pultrusion. The input material is a mix of liquid resin and reinforcing fiber. The material is machinedrawn over a heated steel mold.

The reinforcing material – usually glass fiber – is input as rovings and mats. Rovings, which are spools of wound fiber, are loaded into the rectifier, which distributes the rovings evenly throughout the workpiece cross-section and aligns the position of the mats.

All PREFEN profiles except solid bars have a thin subsurface polyester veil, saturated in resin. This serves to confine the reinforcing fibers to the interior of the piece and improves the chemical and UV resistance of the material, as well as its appearance. In the event of damage, the veil prevents the fibers from protruding out.

The next machine in the line soaks the fiber, mat, and veil in a liquid mix of resin, filler, coloring, catalyst, and optionally further admixtures to improve the material’s physical properties.

Once out of the bath, the workpiece has the general shape of the final product. It then enters another rectifier, which presses out excess resin and further shapes the piece, which is then passed to the hardening mold.

The heated mold is where the thermosetic reaction takes place and the piece hardens.

The finished material is machine-drawn out of the mold and cut into bars of required length – usually 6,000 mm.

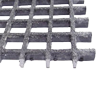

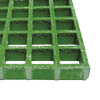

Moulding

is used for production of molded gratings PREFAGRID.

| HEIGHT | |||||

|---|---|---|---|---|---|

| 14 mm | 20 mm and 25 mm | 30 mm | 38 mm | 50 mm | 60 mm |

|

|

|

|

|

|

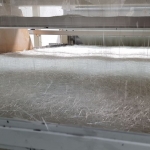

Gratings in form of a square grid pattern are produced from polyester resin reinforced only with unidirectional rovings (without mats and subsurfacing veils in contrast to the assembled, bar-type gratings).

After filling, the mold is heated and the chemical reaction completely cures the product, which is then demolded and after processing is ready for further use.

The walking surface is provided with an anti-skid layer consisting of quartz sand embedded into epoxide resin.

Molded grating is edge bearing and can rest on all four sides. This is an asset as far as the structural rigidity is concerned.

PREFAGRID gratings are produced in large plates, which are then divided according to customer requirements. The plates have different maximum dimensions. The largest dimension is 1,220 x 4,660 mm. However, in specific cases it is necessary to check their availability with our sales representatives.

Manual lamination

Lamination technology types:

- Pressing

- Manual lamination

- Spraying (may be combined with manual lamination)

Manual lamination

Manual lamination consists of adding successive layers of resin and fiber into a mold. The matrix is usually polyester resin; the reinforcing fiber is glass, mainly mats, optionally with rovings.

We use manual lamination to manufacture all cover surfaces and edges; complex shapes are also possible. This method allows affordable production of small orders that would otherwise suffer from machinery setup costs.

Sprayed products

Spraying consists of using a spraying machine to deposit a mix of resin and short glass fibers into a mold or directly onto a surface. This method requires a degree of skill and experience in spraying, preparing the surface to be sprayed, and preparing the liquid material.

We primarily use spraying to manufacture bulky parts and to repair damaged surfaces of other materials (mainly concrete and metal).

PRESSING

In molding technology, SMC (Sheet Molding Compound), BMC (Bulk Molding Compound) and prepregs are used. These materials are sized and placed in a mold where they are formed into the desired shape by heat and pressure and then cured.

Our pressing machine specifications:

- Pressing table surface 1,120 x 1,320 mm

- Maximum pressing force 1,000 tons

- Hardening temperatures up to 200 degrees Celsius

SMC

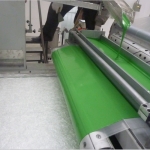

SMC (Sheet Molding Compound) is a composite material consisting mainly of thermosetting resin (usually polyester) and chopped fiberglass, which is produced in sheet form. These sheets can be cut into pieces of the required size, which are superimposed on each other and are formed into the desired shape and cured in the press under heat and pressure. SMC materials are widely used in the construction, electrical and automotive industries.

The production of SMC is a continuous process in which the resin in a thin layer is spread on a plastic film. It passes under the machine, chopping glass fibers, which are uniformly applied to the resin layer. Subsequently, the fiber layer is covered by a second resin layer, which is also applied to the plastic film. This sheet is then passed through a roll system and the fibers are compacted and saturated. After compaction, the material can be wound on reels or stacked. The sheets can be stored for up to 3 months.

SMC technology allows the use of materials with a fiber content of 15% to 65%. The length of the fibers is generally 25 or 50 mm, but it is possible to produce SMC even with fabrics or continuous fibers. Thermoplastic additives, catalysts, inhibitors, separators, thickeners and pigments are used to improve the final properties of the product and molding process.

BMC

BMC (Bulk Molding Compound) is a composite material consisting mainly of thermosetting resin (most often polyester) and fiberglass (length <25 mm). BMC is used primarily for the production of products by pressing or injection molding, which is then formed into the desired shape and cured under heat and pressure.

BMC materials are widely used in the construction, wiring and automotive industries. BMC is also applied in industry, services, households and medicine.

BMC production

BMC is a polymer composite material that is made by mixing chopped glass fibers with a thermosetting resin and mineral fillers. The resins used are most commonly unsaturated polyester or vinyl ester resins. Thermoplastic additives, catalysts, inhibitors, separators, thickeners and pigments are used to improve the final properties of the product and molding process.

PREFEN – product characteristics

PREFEN 505

| resin | isophthalic polyester |

|---|---|

| standard color | light grey |

| UV stabilizer | included |

| application | general use |

PREFEN 525

| resin | isophthalic polyester with fire interaction class B |

|---|---|

| standard color | light grey |

| UV stabilizer | included |

| application | generally for reduced flammability |

PREFEN 535

| resin | isophthalic polyester with fire interaction class A |

|---|---|

| standard color | light grey |

| UV stabilizer | included |

| application | generally for reduced flammability |

PREFEN 536

| resin | isophthalic polyester with fire interaction class A |

|---|---|

| standard color | dark grey |

| UV stabilizer | excluded |

| electrostatics | included |

| application | generally for reduced flammability and avoidance of static electricity |

PREFEN 605

| resin | vinyl ester |

|---|---|

| standard color | grey |

| UV stabilizer | included |

| application | structions in highly corrosive environment |

PREFEN 625

| resin | vinyl ester with fire interaction class B |

|---|---|

| standard color | grey |

| UV stabilizer | included |

| application | energy industry products |

PREFEN 700

| resin | epoxy with carbon fiber |

|---|---|

| standard color | black |

| UV stabilizer | excluded |

| application | reinforcement of concrete structures and foundations |

KEY FEATURES OF PREFEN PROFILES

PREFEN structural composite pultruded profiles offer many advantages:

- Low weight

Easy and safe handling – up to 4 times lighter than steel (nominal density 1,800 Kg/m³) - Flexible

Unlike metals, composite does not permanently deform when subjected to impact or overload - Chemically stable

Composites are highly resistant against a variety of chemicals, do not corrode in air, and do not require painting or other protective finishing - Electrically non-conductive

Composite structures do not need grounding and are suitable for applications with electrocution, lightning, and wandering current risks - Easy machining

Composites are easy to machine, with a cutting resistance on par with hardwood. Furthermore, composite machining does not create the hazardous sharp edges and splinters produced by steel. - UV resistant

Ultraviolet radiation is a natural component of sunlight and generally tends to degrade organic materials. PREFEN composites feature three-level UV protection: The resin includes UV stabilizing agents, the subsurface polyester veil absorbs some UV, and structures for high-exposure applications are painted with polyurethane to prevent long-term discoloration. - High service life

The useful service life of composite materials depends on a variety of factors, the most important of which are aggressive chemicals, weather conditions (temperature, humidity, subzero conditions), UV exposure, and high-temperature environments. Our technology department will review your requirements and propose a suitable material solution. Assuming operational requirements are met, composite materials generally last for the lifetime of the structure. - Hygienically safe

PREFEN is officially attested safe for immersion in potable water. - Excellent mechanical strength

Tensile strength from 240 to 1,000 MPa with glass fiber; up to 3,000 MPa with carbon fiber - Fire-retardant

Thanks to fire-retardant admixtures, we can supply materials with fire interaction class (pursuant to ČSN EN 13501-1) Bfl – s1 for flooring materials; C – s2, d0 for other materials. - Nominal thermal conductivity

As low as 0,19 W.m-1.K-1 in materials with thermal bridge suppression requirements - Sustained thermal resistance

Between 100 and 180 °C, depending on resin type - Surface resistivity

Standard materials on the order of 1012 Ohm; upon request as low as 106 Ohm