References

More examples of applications can be found in the references: water management, transport construction, chemistry and more

Details

GRATINGS TYPES

- PREFAPOR assembled gratings composed of pultruded beams; contain up to 70% glass fiber.

- PREFAGRID molded gratings; contain up to 40% glass fiber.

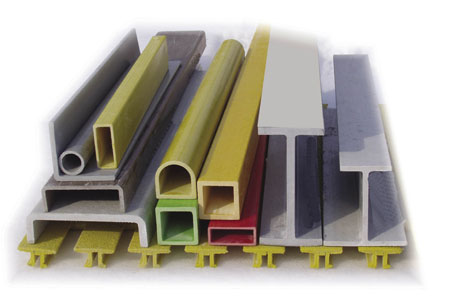

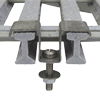

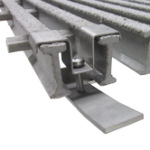

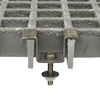

ACCESSORIES

Stainless steel gratings anchors, shaped to match anchor eye (moulded gratings) or support leg (assembled gratings) thickness.

COLORS

The standard color is grey; for larger orders, consult our sales department for custom colors (green, yellow, and others).

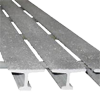

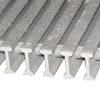

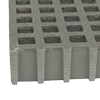

PREFAPOR ASSEMBLED GRATINGS

KEY FEATURES

- Pultrusion technology allows the use of subsurface veil, which protect the material

from corrosive environments. - Up to 70% glass fiber; allows the use of fiber mats

- Longer service life

- Higher shock resistance

- Panels of arbitrary length can be made (unlike moulding, which is limited by mold size)

- Anti-slip surface

DRAWBACKS

- Can only be supported perpendicular to loadbearing element axis

- Not suitable for pipe pass-through apertures

ASSEMBLED GRATINGS TYPES

| type | plate width [mm] |

gap width [mm] |

height [mm] |

weight [kg/m2] |

|---|---|---|---|---|

| 1. PREFAPOR 15 x 23/ 25 | 15 | 23 | 25 | 12.0 |

| 2. PREFAPOR 15 x 10/ 25 | 15 | 10 | 25 | 15.0 |

| 3. PREFAPOR 40 x 10/ 25 | 40 | 10 | 25 | 13.0 |

| 4. PREFAPOR 15 x 23/ 32 | 15 | 23 | 32 | 13.5 |

| 5. PREFAPOR 15 x 23/ 38 | 15 | 23 | 38 | 16.1 |

| 6. PREFAPOR 15 x 10/ 38 | 15 | 10 | 38 | 22.0 |

| 7. PREFAPOR 25 x 25/ 50 | 25 | 25 | 50 | 15.1 |

NOTE: Custom sizes available (length in load-bearing direction up to 4,000 mm; width up to 1,500 mm)

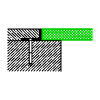

| 1. | 2. | 3. | 4. + 5. | 6. | 7. |

|---|---|---|---|---|---|

|

|

|

|

|

|

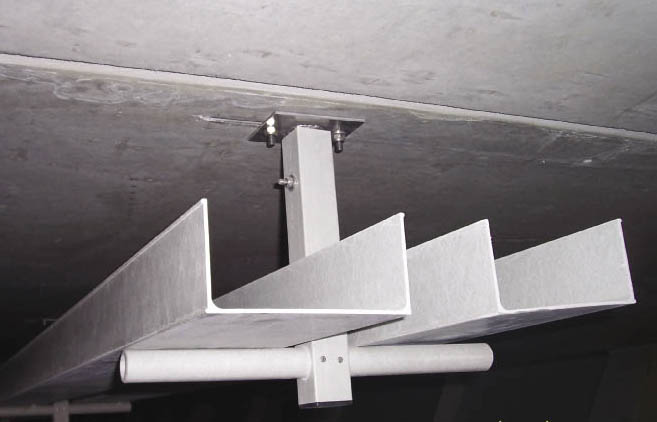

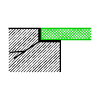

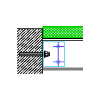

ASSEMBLED GRATINGS ANCHORING

|

|

|

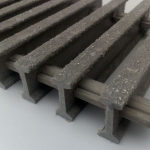

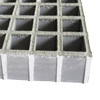

PREFAGRID MOULDED GRATINGS

KEY FEATURES

- Higher stiff ness (reinforcing fibers laid in two perpendicular axes)

- Can be supported at all four sides

- Can be cut to any shape

- Pipe pass-through apertures can be cut

- Anti-slip surface

DRAWBACKS

- Moulding technology is incompatible with subsurface veil

- Reinforcing fiber share is only about half that of assembled gratings

- Lower shock resistance

- Maximum dimensions limited by available molds

MOULDED GRATINGS TYPES

| type | eye size [mm] |

height [mm] |

weight [kg/m2] |

standard panel sizes [mm] |

|---|---|---|---|---|

| 1. PREFAGRID 44 x 44/14 | 44 x 44 | 14 | 5.8 | 1,220 x 3,660 |

| 2. PREFAGRID 30 x 30/20 | 30 x 30 | 20 | 10.0 | 1,220 x 3,660 |

| 3. PREFAGRID 30 x 30/25 | 30 x 30 | 25 | 12.0 | 920 x 2,800; 1,007 x 2,800; 1,000 x 3,000; 1,220 x 3,660; 1,220 x 4,000 |

| 4. PREFAGRID 30 x 30/30 | 30 x 30 | 30 | 14.6 | 920 x 2,800; 920 x 3,050; 1,000 x 3,000; 1,000 x 4,000; 1,220 x 2,100; 1,220 x 3,660 |

| 5. PREFAGRID 30 x 30/38 | 30 x 30 | 38 | 19.5 | 1,000 x 3,660; 1,000 x 4,000; 1,220 x 2,100; 1,220 x 3,660; 1,220 x 4,000 |

| 6. PREFAGRID 44 x 44/50 | 44 x 44 | 50 | 23.5 | 970 x 2,250; 970 x 3,660; 1,220 x 3,660 |

| 7. PREFAGRID 30 x 30/60 | 30 x 30 | 60 | 50.0 | 770 x 1,383; 1,000 x 3,660; 1,220 x 3,660 |

NOTE: Custom shapes and sizes available upon request

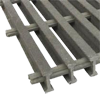

| 1. | 2. + 3. | 4. | 5. | 6. | 7. |

|---|---|---|---|---|---|

|

|

|

|

|

|

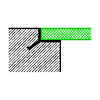

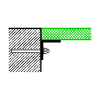

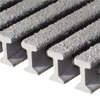

MOULDED GRATINGS ANCHORING

|

|

|

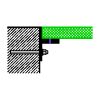

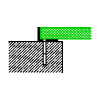

GRATING MOUNTING OPTIONS

PREFAPOR ASSEMBLED GRATING MAXIMUM LOAD

CONTINUOUS LOAD [kg/m2]

| type | SPAN BETWEEN SUPPORTS [mm] | |||||||

|---|---|---|---|---|---|---|---|---|

| 500 | 600 | 700 | 800 | 900 | 1,000 | 1,100 | 1,200 | |

| PREFAPOR 15×23/25 | 5,820 | 3,370 | 2,120 | 1,330 | 830 | 550 | 370 | 260 |

| PREFAPOR 15×10/25 | 8,530 | 4,940 | 3,110 | 1,950 | 1,220 | 800 | 550 | 390 |

| PREFAPOR 40×10/25 | 10,460 | 6,050 | 3,810 | 2,390 | 1,490 | 980 | 670 | 470 |

| PREFAPOR 15×23/32 | 11,640 | 6,730 | 4,240 | 2,660 | 1,660 | 1,090 | 750 | 530 |

| PREFAPOR 15×23/38 | 13,240 | 9,010 | 5,670 | 3,560 | 2,230 | 1,460 | 1,000 | 700 |

| PREFAPOR 15×10/38 | 14,120 | 9,260 | 6,860 | 4,310 | 2,690 | 1,760 | 1,210 | 850 |

| PREFAPOR 25×25/50 | 16,340 | 11,820 | 8,430 | 6,230 | 3,890 | 2,550 | 1,740 | 1,230 |

NOTE: For two-support mounting. Criterion: sagging l/125, max. 6 mm.

ISOLATED FORCE LOAD [kg]

| type | SPAN BETWEEN SUPPORTS [mm] | |||||||

|---|---|---|---|---|---|---|---|---|

| 500 | 600 | 700 | 800 | 900 | 1,000 | 1,100 | 1,200 | |

| PREFAPOR 15×23/25 | 920 | 500 | 320 | 240 | 190 | 150 | 110 | 90 |

| PREFAPOR 15×10/25 | 1,310 | 810 | 530 | 380 | 280 | 210 | 160 | 130 |

| PREFAPOR 40×10/25 | 910 | 590 | 410 | 270 | 190 | 170 | 130 | 100 |

| PREFAPOR 15×23/32 | 1,150 | 670 | 450 | 320 | 240 | 190 | 140 | 110 |

| PREFAPOR 15×23/38 | 1,940 | 1,180 | 790 | 570 | 420 | 330 | 250 | 200 |

| PREFAPOR 15×10/38 | 2,910 | 1,830 | 1,250 | 890 | 670 | 500 | 400 | 320 |

| PREFAPOR 25×25/50 | 2,360 | 1,620 | 1,060 | 800 | 620 | 480 | 380 | 310 |

NOTE: Values for two-support mounting with load applied at grating geometric center, pursuant to EN 124. For load applied to unsupported edge, the deformation is about twice the value listed.

Criterion: sagging l/125, max. 6 mm.

PREFAGRID MOULDED GRATINGS MAXIMUM LOAD

CONTINUOUS LOAD [kg/m2]

| type | SPAN BETWEEN SUPPORTS [mm] | |||||||

|---|---|---|---|---|---|---|---|---|

| 500 | 600 | 700 | 800 | 900 | 1,000 | 1,100 | 1,200 | |

| PREFAGRID 30×30/25 | 1,450 | 840 | 530 | 330 | 210 | 140 | 90 | 70 |

| PREFAGRID 30×30/30 | 2,780 | 1,610 | 1,010 | 640 | 400 | 260 | 180 | 130 |

| PREFAGRID 30×30/38 | 4,270 | 2,470 | 1,550 | 980 | 610 | 400 | 270 | 190 |

| PREFAGRID 44×44/50 | 7,660 | 5,220 | 3,290 | 2,060 | 1,290 | 850 | 580 | 410 |

| PREFAGRID 30×30/60 | 20,180 | 14,180 | 10,510 | 6,600 | 4,120 | 2,700 | 1,850 | 1,300 |

NOTE: For two-support mounting. Criterion: sagging l/125, max. 6 mm.

ISOLATED FORCE LOAD [kg]

| type | SPAN BETWEEN SUPPORTS [mm] | |||||||

|---|---|---|---|---|---|---|---|---|

| 500 | 600 | 700 | 800 | 900 | 1,000 | 1,100 | 1,200 | |

| PREFAGRID 30×30/25 | 350 | 210 | 150 | 100 | 70 | 60 | 50 | 40 |

| PREFAGRID 30×30/30 | 760 | 450 | 270 | 190 | 140 | 110 | 80 | 60 |

| PREFAGRID 30×30/38 | 1,030 | 670 | 420 | 290 | 210 | 160 | 120 | 100 |

| PREFAGRID 44×44/50 | 2,270 | 1,370 | 940 | 650 | 490 | 340 | 280 | 220 |

| PREFAGRID 30×30/60 | 4,880 | 3,300 | 2,060 | 1,440 | 1,130 | 790 | 640 | 510 |

NOTE: Values for two-support mounting with load applied at grating geometric center, pursuant to EN 124. For load applied to unsupported edge, the deformation is about twice the value listed.

Criterion: sagging l/125, max. 6 mm.

![Back to homepage [PREFA KOMPOZITY,a.s. logo]](https://www.prefa-kompozity.cz/en/wp-content/themes/prefakompozityen/images/prefa-kompozity-logo-new.png)